|

High carbon anthracite, often referred to as "hard coal," is one of the most versatile and valuable forms of coal. Known for its high carbon content, low impurities, and high energy density, this type of anthracite has a wide range of applications that span across various industries. In this blog, we will explore the myriad uses of high carbon anthracite, highlighting its significance and impact on modern industry and technology.

0 Comments

Anthracite is the highest rank of coal. It's also known as hard coal, is a hard, compact variety of coal with a submetallic brightness. Another feature that distinguishes Anthracite from other coals is that this type of coal is considered a metamorphic rock. Anthracite has the highest carbon content, least impurities, and highest energy density among all coal varieties and is the highest coal ranking. It is the most fragile of the charcoal types, producing a scorching blue flame when burned. The low sulfur content in Anthracite makes it an extremely clean-burning fuel. Therefore, it is the most environmentally friendly type of coal among coal types. Brief History Of Anthracite Coal Anthracite was formed during the Carboniferous Age when the dense green vegetation that thrived during the tropical climate of the time fossilized. Anthracite is a type of organic coal formed by the fossilization of green vegetation growing in a tropical environment in the Carboniferous Age. Anthracite derives from the Greek word anthrakítēs, which is "like coal". Anthracite has been providing even, using in locomotive trains, industrial buildings, houses throughout the world for nearly 200 years. In the past, Anthracite was also used in homes for reasons such as low dust and smoke emission, slow and prolonged burning, and high heating capacity. Today, there are alternatives such as natural gas, and its price is high due to decreasing interactive reserves. Today, anthracite reserves are limited, and their small amount has led to the use of this high-capacity coal type for more industrial purposes. In the past, Anthracite was also used in homes for reasons such as low dust and smoke emission, slow and prolonged burning, and high heating capacity. Nowadays, there are alternatives such as natural gas, and its price is high due to decreasing interactive reserves. New technology and engineering design changes to burners have made it even easier to use. Anthracite coal does not leave creosote residue in the chimney. In this way, it does not cause a fire hazard like cordwood and pellet-burning stoves. How Anthracite Occurs As the temperature of the ground increases, organic matter called peat turns into lignite, hard coal, Anthracite, respectively, and graphite if suitable conditions occur. This transformation process is called carbonization. If the carbon content is 60%, it is called peat, 70% is lignite, 80-90% is hard coal, and 95% is Anthracite. Anthracite is the purest form of coal, in which the carbon content is between 86% and 98%. It's divided into subspecies according to the ratio and structure of carbon content. These; semi-anthracite, anthracite, and meta-anthracite. Anthracite is coal, which is found in minimal amounts in nature, is the type of coal with the highest heat quality when compared to other coal types. Only %5 of the world's total coal is Anthracite. South Africa, the USA, China, Russia, Ukraine, North Korea, Vietnam, UK, Australia, and Canada are the countries where Anthracite is mined. Anthracite Coal Heating Value Anthracite is the type of coal with the highest energy release, ie, heat value, among coal types (about 900 degrees or higher). It produces more than 100 thousand joules of energy per kilogram. We are happy to announce that Kayoo Group is now a licensed international coal trading entity by world's leading online physical coal trading platform, globalCOAL

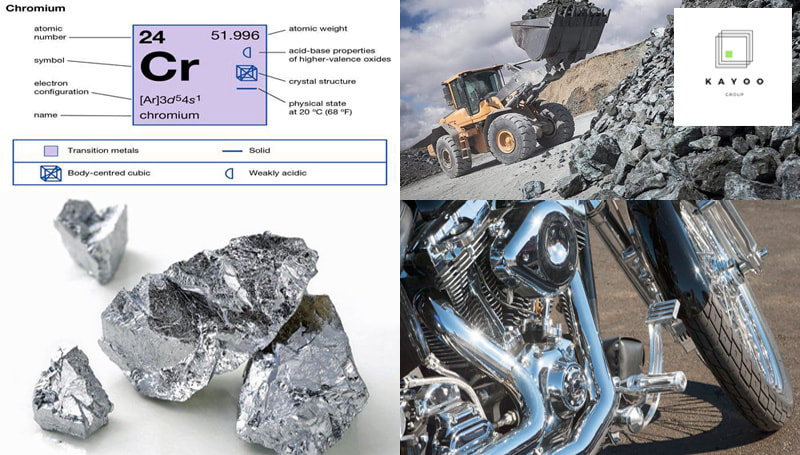

Why is this important? globalCoal Standard Coal Trading Agreement (SCoTA®) is widely recognised as the contract of choice for the sale and purchase of seaborne thermal coal. As a licensed entity, Kayoo Group joins Glencore, Anglo America and over 2,500 licensees worldwide who leverage SCoTA accepted set of standard terms and conditions together with a range of coal quality specifications and delivery points for international coal sales and purchases. Ferro Alloys made by iron with one or more elements such as manganese (Mn), aluminum (Al) or silicon (Si) chromium (Cr) are called ferroalloys.

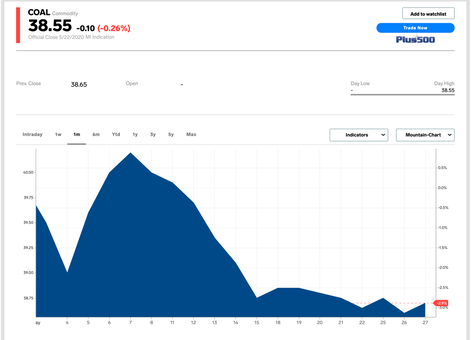

Ferroalloys are used in steel and alloy production. When ferroalloys are mixed with cast iron and steel, they add different properties to the products and change their qualities. For this reason, ditches are used in the iron and steel industry. The world's leading ferroalloy producing countries are South Africa, Ukraine, China and Russia. Correction of steel quality using ferroalloys improves mechanical performance. Correction in steel quality will also increase the resistance to temperature changes. Thus, it is possible to obtain steel mixtures with high mechanical performance and heat resistance by using ferroalloys. Ferro Alloys Raw Materials Ferroalloys are formed by mixing a specific group of elements and a saturated ore. Enriched ore is used to obtain ferrosilicon and ferrochromium. In order to obtain ferrotitanium and ferrotungsten, the result is obtained by concentrating the raw material. The reduction of metal oxides in the compounds is a technology requiring process. In processes with ferroalloys, the catalysts of the reaction are iron and oxides. The restored element takes some conditions to create a stable form. The element also takes its absence for reverse oxidation. In these stages, the electrothermal method that produces ferroalloys is used in the metallurgy industry. Chromium is chiefly obtained from the mineral chromite. Basic Chromium mines located in South Africa, Kazakhstan, India, Albania, and Turkey. South Africa is the largest producer of chromium with amounting to 17 million metric tons annual capacity. Chromite concentrate, when combined with a reductant such as coal or coke and a high-temperature furnace can produce ferrochrome. Ferrochrome is a type of ferroalloy that is an alloy in between chromium and iron. Chromium allows for the stainless steel to be much harder and tougher. In addition, it prevents corrosion on iron and steel surfaces due to high temperatures. Shredded chromite ore is used to produce stainless steel. Earlier this month, the International Energy Agency predicted the effects of the COVID-19 virus would see thermal coal demand decline worldwide by 8%, the biggest drop since the Second World War.

Seaborne thermal coal prices this year have also fallen by about 20%, again due to declining demand as factories and offices stayed closed, meaning a substantial reduction in power demand. Coal is a fossil fuel consisting mainly of carbon, which has been used as the primary energy source for more than a century. it is widely used across a number of industries.

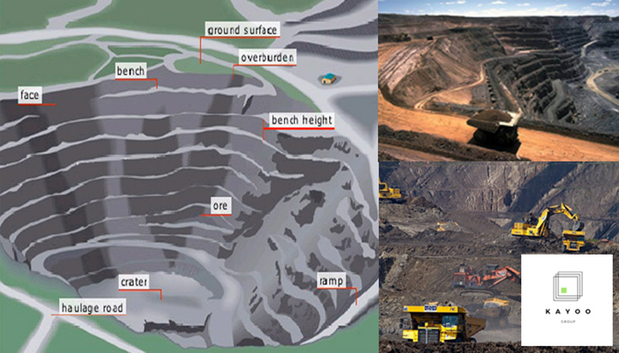

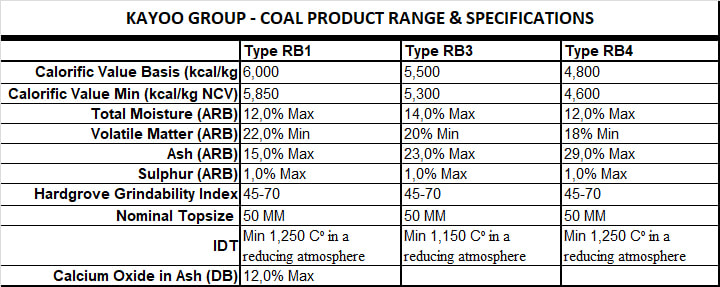

Contrary to popular belief, Coal is still the world’s fastest-growing energy source. Compared to other energy sources such as gas, oil, nuclear energy, using coal as an energy source is still much more affordable. The global coal industry is feed from the world’s biggest mines, which mainly consist of fossil fuel. Mining is also a sector that provides significant employment, offers safer mining opportunities with modern technology. There are four main mining methods: underground, open surface (pit), placer, and in-situ mining.  Overview Coal is the most common and longest used fossil energy fuel. Coal, oil and natural gas will still exist when depleted, and coal prices are stable compared to other energy sources. Coal is a safe and reliable product because of its ease of transportation, ease of storage and long life. It is also easy to process and deliver coal to users. With such properties, coal is an indispensable source of energy. World oil reserves will run out in 40 years, according to estimates. Natural gas reserves will be exhausted after 60 years. Estimates for coal reserves are around 200 years. It has been the fastest-growing energy source worldwide in the 21st century and also it will be the long-term efficient energy product in the near future. Coal is a fossil fuel. Its main components are; carbon, hydrogen, and oxygen. Steam coal is also known as thermal coal. It’s mostly used in electricity generation. Thermal Coal products in South Africa South Africa is the 6th biggest coal exporter country with 6,23 billion USD export value. 1/4 of South African coal is exported to energy providers and metallurgical plants in mostly Europe, South America, and India. Coal is highly used as energy source in South Africa, almost 90% of South Africa electricity being obtained from coal-fired power stations. Supporters of environmentalist products compare wind and solar power and electricity generation capacity and storage issues with the cost of natural gas production and the security risks posed by nuclear power plants. The result is clear, coal will remain an economic and reliable source of energy for the next 50 years. It is no coincidence that South African coal is used in the energy sector and especially in electricity generation. South Africa's RB1 and RB3 type coals offer high-calorific value and high energy efficiency. Other features that make South African coal advantageous are its ability to burn easily and fast, soft and brittle. Analysing and specification of Coal The type and basic properties of coal are determined by the properties measured in 8 main titles. Such as: "gross calorific value", "total moisture", "volatile matter", ash, "total sulphur" and so on. The specification for thermal coal is defined in terms of its typical quality. Coal trading companies request additional analyses and test records on milling, ash composition, and ash fusion temperatures as a standard procedure. SOUTH AFRICAN COAL SPECIFICATIONS - RB1, RB3, RB4/4800 |

Archives

May 2024

Categories |

RSS Feed

RSS Feed