|

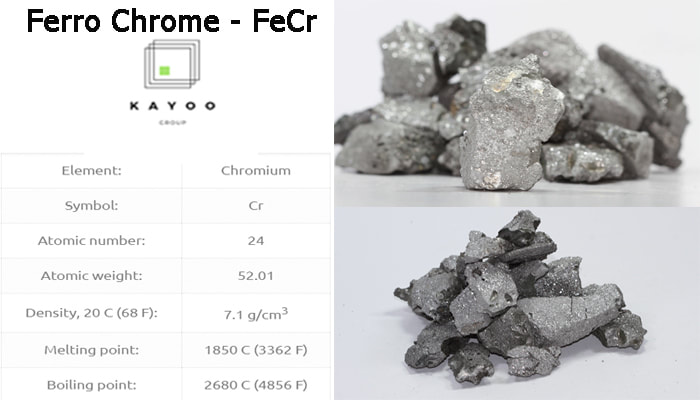

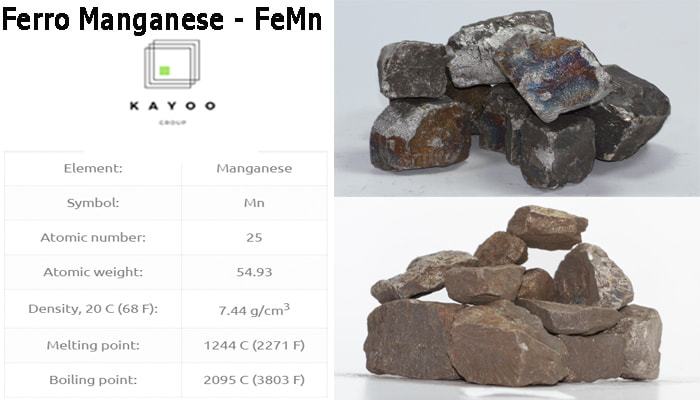

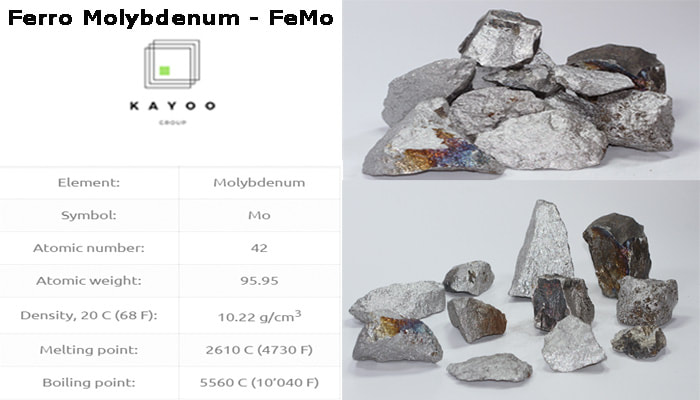

Ferro Alloys made by iron with one or more elements such as manganese (Mn), aluminum (Al) or silicon (Si) chromium (Cr) are called ferroalloys. Ferroalloys are used in steel and alloy production. When ferroalloys are mixed with cast iron and steel, they add different properties to the products and change their qualities. For this reason, ditches are used in the iron and steel industry. The world's leading ferroalloy producing countries are South Africa, Ukraine, China and Russia. Correction of steel quality using ferroalloys improves mechanical performance. Correction in steel quality will also increase the resistance to temperature changes. Thus, it is possible to obtain steel mixtures with high mechanical performance and heat resistance by using ferroalloys. Ferro Alloys Raw Materials Ferroalloys are formed by mixing a specific group of elements and a saturated ore. Enriched ore is used to obtain ferrosilicon and ferrochromium. In order to obtain ferrotitanium and ferrotungsten, the result is obtained by concentrating the raw material. The reduction of metal oxides in the compounds is a technology requiring process. In processes with ferroalloys, the catalysts of the reaction are iron and oxides. The restored element takes some conditions to create a stable form. The element also takes its absence for reverse oxidation. In these stages, the electrothermal method that produces ferroalloys is used in the metallurgy industry. Ferro Chrome – FeCrFerro-chrome is added to steel to impart properties of hardness, strength and making it stainless. High Carbon Ferro Chrome is most commonly used in specialist applications such as engineering steels. Ferro Chrome is the most consumed area in steel production. Ferro Chrome is an important product, especially in Stainless Steel's production with Chromium content between 10% and 20%. Since the main product that supports Stainless Steel's appearance and its resistance against corrosion is chrome, Ferro Chrome is important in the sector. Low-carbon Ferro-Chrome is used during steel production to correct chrome percentages. It is also a low-cost alternative to metallic chrome for uses in superalloys and other special melting applications. PRODUCT SIZE: 4-10 mm / 10-50 mm / 10-80 mm / 10-100 mm Pacakaging: Bulk or 1 mt big-bag EXPORT PRICE & MOQ: Please contact us to get a quote Ferro Manganese - FeMnChemically, it generally behaves similar to iron. In metal form, manganese is oxidized outdoors and rusts in a humid environment. It burns with air or oxygen at high temperatures, similar to iron. Ferro-manganese is used mainly in the steel industry to harden and desulphurize steel and as a deoxidizer, making the slag more fluid. Ferro Manganese is a ferroalloy containing high manganese levels, and it is a product that provides deoxidization in steel. FerroMangan LC is a FerroMangan alloy containing low carbon. Especially in steel production, it is frequently used to adjust the Manganese ratio without increasing the carbon ratio. PRODUCT SIZE: 1-3 mm / 3-10 mm / 10-50 mm / 10-100 mm Packaging: Bulk or 1 mt big-bag EXPORT PRICE & MOQ: Please contact us to get a quote Ferro Silicon Manganese – FeSi FeSiMn is used as a deoxidant and alloying element in steel production. According to the usage rates of FerroSilis and FerroMangan, FeSiMn can be preferred instead of both. It provides a cost advantage in steel production compared to FerroSilis and FerroMangan consumption. Ferro Silico Manganese is used as a deoxidizer and an alloying element in steel. It can be used as a substitute for Ferro Silicon and Ferro Manganese when added to make different steel types. PRODUCT SIZE: 1-3 mm / 3-10 mm / 10-50 mm / 10-100 mm Packaging: Bulk or 1 mt big-bag EXPORT PRICE & MOQ: Please contact us to get a quote Ferro Molybdenum – FeMoChemically it is generally similar to iron. It burns with air or oxygen at high temperatures like iron. Ferro Molybdenum is one of the main products used in molybdenum alloying of High Strength-Low Alloy (HSLA) Steel. Ferro molybdenum can be used in any melting process to add all kinds of molybdenum to iron and steel and is available in a variety of sizes for furnace or ladle attachment. Ferro molybdenum is used during alloying with steel by adding it into the molten steel before casting, making the steel extremely robust and increasing the product's resistance to corrosion. The most important use of manganese is iron and steel production, in which ferromanganese and silica-manganese iron are used as products. PRODUCT SIZE: 10-50 mm / 10-100 mm Packaging: Bulk or 1 mt big-bag EXPORT PRICE & MOQ: Please contact us to get a quote Kayoogroup is trading, marketing and procurement service provider for commodities in the mining industry.

Kayoogroup provides an expert support service in the South African market for Ferro Alloys include Ferro Chrome, Ferro Manganese, Silicon Manganese and Ferro Molibden (FeMo) With its wide range of products, our company is at the service of all companies wishing to cooperate with an experienced local partner in the African market. For more information email us at [email protected] or call +27 78 777 7298

1 Comment

KOTA SHIVAAJI

4/8/2021 08:44:55 pm

Good Day

Reply

Leave a Reply. |

Archives

May 2024

Categories |

RSS Feed

RSS Feed